Ascon Systems transforms the

Pharma & Chemical Industry

The next-gen process automation and orchestration platform Ascon Qube revolutionizes pharmaceutical and chemical production by enabling greater precision, compliance, and agility. Ascon Qube empowers pharmaceutical manufacturers to implement good outstanding manufacturing production practices and achieve a new level of efficiency. All while keeping pace with regulatory demands and technological advancements from personalized medicine to biotechnology or fine, consumer or specialty chemicals.

World-leading companies trust us

The Challenges

Mounting challenges in pharmaceutical & chemical production

Pharmaceutical and chemical manufacturers face significant challenges to meet regulatory requirements, ensure product quality and ensure supply chain integrity. These include:

- Strict validation and documentation requirements

- Complex deviation management that requires precise tracking

- High traceability requirements that require seamless coordination across the entire supply chain

- Incremental optimizations that cannot keep pace with innovations

What you need is a scalable, software-based automation solution that ensures compliance while enabling new levels of operational efficiency and adaptability.

Ascon Qube

Your partner in precision and compliance

The Ascon Qube automation platform offers extensive automation and orchestration for production and manufacturing, where you model processes instead of programming.

Ensure compliance with even the most stringent regulatory standards and achieve unprecedented agility and precision through flexibly adaptable processes.

Thanks to a software-defined approach, Ascon Qube simplifies complex processes, from validation to traceability.

Automation and process orchestration

Pharmaceutical and chemical production requires precision and scalability to manage complex workflows. Ascon Qube enables process flows to be modeled and operations to be managed, controlled and optimized using advanced, bidirectional digital twins.

Automated compliance checks and real-time insights ensure regulatory requirements are met without compromising efficiency or quality.

Data transparency

End-to-end data visibility provides a constantly updated and contextualized view of production data so you can monitor, analyze and optimize your production in near real-time. It also ensures full traceability across the entire supply chain and supports regulatory compliance.

With detailed insights into every manufacturing stage from raw materials to finished product, you can optimize quality control and respond faster to deviations.

Digital Twin technology

In a globally connected and highly regulated industry, seamless collaboration is crucial. Plan, control, visualize and optimize the production of pharmaceuticals and chemicals using our unique bidirectional Digital Twin technology.

Collaborate virtually and integrate data and systems for real-time visibility and control.

End-to-end visibility

Effective planning is the backbone of successful chemical and pharmaceutical production. Ascon Qube ensures a consistent, closed data flow in all project phases, from the early development phase to series production.

Conclusions and learnings, as well as better resource distribution, are facilitated.

Interfaces to all types of hardware and software improve efficiency, transparency and enable an active dismantling of IT and OT silos.

Benefits

Transformational Benefits for Pharmaceutical and Chemical Manufacturers

Achieve flawless compliance

Navigate the strict regulatory landscape with confidence. Ascon Qube streamlines validation, documentation, and traceability processes, thanks to full data transparency, allowing you to adhere to GMP, GDP and other standards without adding unnecessary complexity.

Optimize resource utilization

Leverage real-time data and predictive analytics to identify inefficiencies and reduce waste. From optimizing energy consumption to minimizing raw material use and yield losses, Ascon Qube helps you unlock significant cost savings.

Accelerate innovation

Reduce time-to-market for crucial products by streamlining production workflows and enabling seamless collaboration. Ascon’s advanced tools empower teams to bring innovative products and treatments to customers faster while maintaining strict quality controls.

Enhance operational agility

Adapt quickly to market demands, regulatory updates, or supply chain disruptions. With Ascon Qube, you can scale production quickly and efficiently, keeping you resilient and future-ready.

Use Case

Bürkert Fluid Control Systems trusts Ascon Qube

Fluidics specialist Bürkert is now using digital twin technology from Ascon Systems to automate, orchestrate and optimize processes across a range of applications including pharmaceuticals and chemicals.

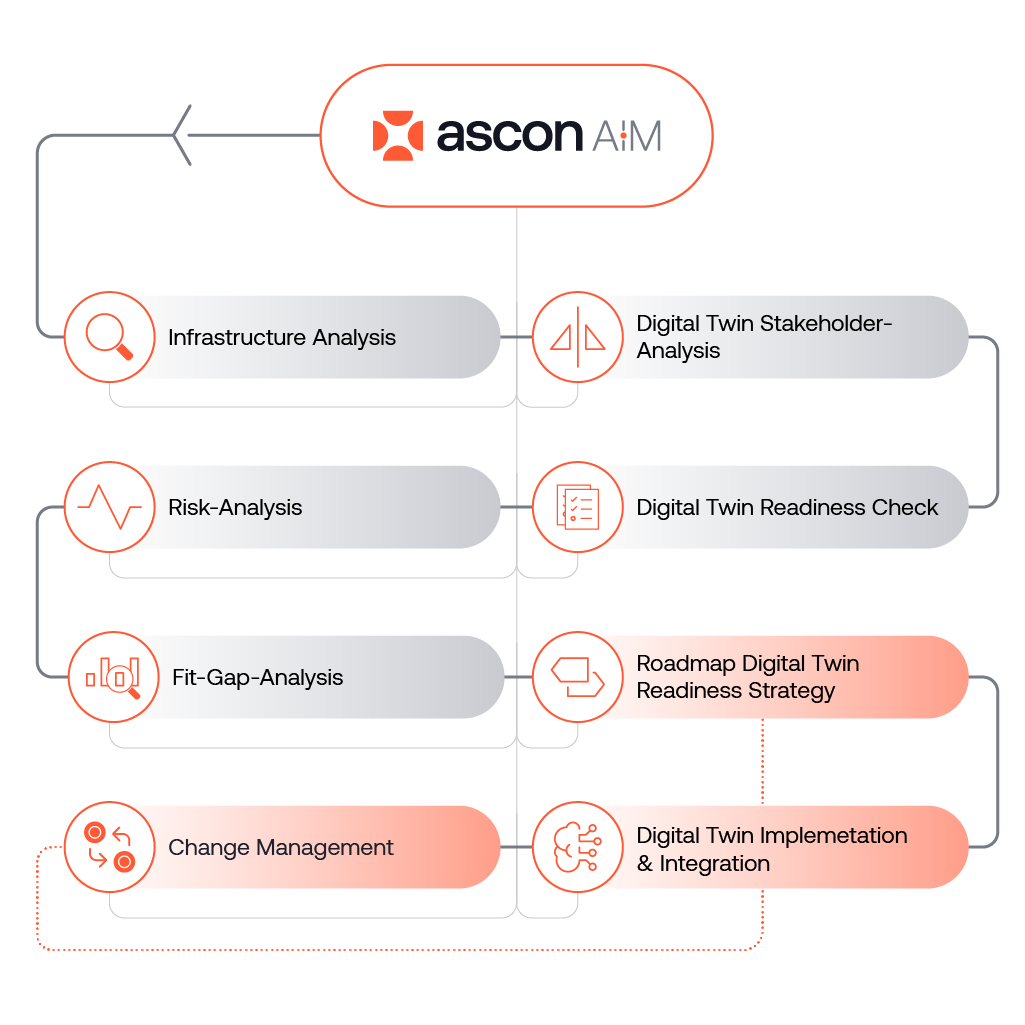

How Ascon Systems can help

Revolutionizing manufacturing operations with cutting-edge technology

Whether you’re modernizing existing facilities or planning a new plant, Ascon Systems has the tools and expertise to transform your operations.

Our proven implementation strategy and transformation service Ascon AIM ensures a smooth, iterative transition to advanced software-defined automation and orchestration. Schedule an appointment today to explore how the Ascon Qube can help you overcome your challenges and achieve your production goals.

Contact us

The time to transform is now!

Book a consultation with our product experts.